Recent Posts

An Overview of Interpower Testing

Posted on 4/22/24 9:57 AM

Whether customized cord sets or electrical components for global industries, Interpower’s cords and cord sets are continually tested beyond UL and IEC standards.

Topics: testing, designing for export, safety, compliance standards, USA Made Products

Swiss Household Plug and Socket System Deviation per SN 441011

Posted on 11/10/20 3:49 PM

The new Swiss standard series SN 441011 for plugs and socket-outlets for household and similar purposes has been applicable since March 1, 2019, and replaces the previous standard SN SEV 1011. The manufacture and import of products and appliances incorporating plugs and socket-outlets that are regulated by the previous standard SN SEV 1011 will remain permitted until February 28, 2022.

Topics: electrical safety, cord set, testing, Swiss plug

Hospital-Grade Cords—Fighting the Good Fight

Posted on 9/14/20 4:46 PM

Whether it’s a hospital in a city or a clinic in a small town, reliable power is critical to medical facility patients, families and staff. Interpower Hospital-grade plugs can be molded or hand-wired in several colors. The color of choice for many hospitals and clinics, however, is the clear, see-through Interpower hospital plug. The clear plug allows medical staff to see if plug wiring and other components remain intact.

Topics: product design, testing, hospital-grade cords

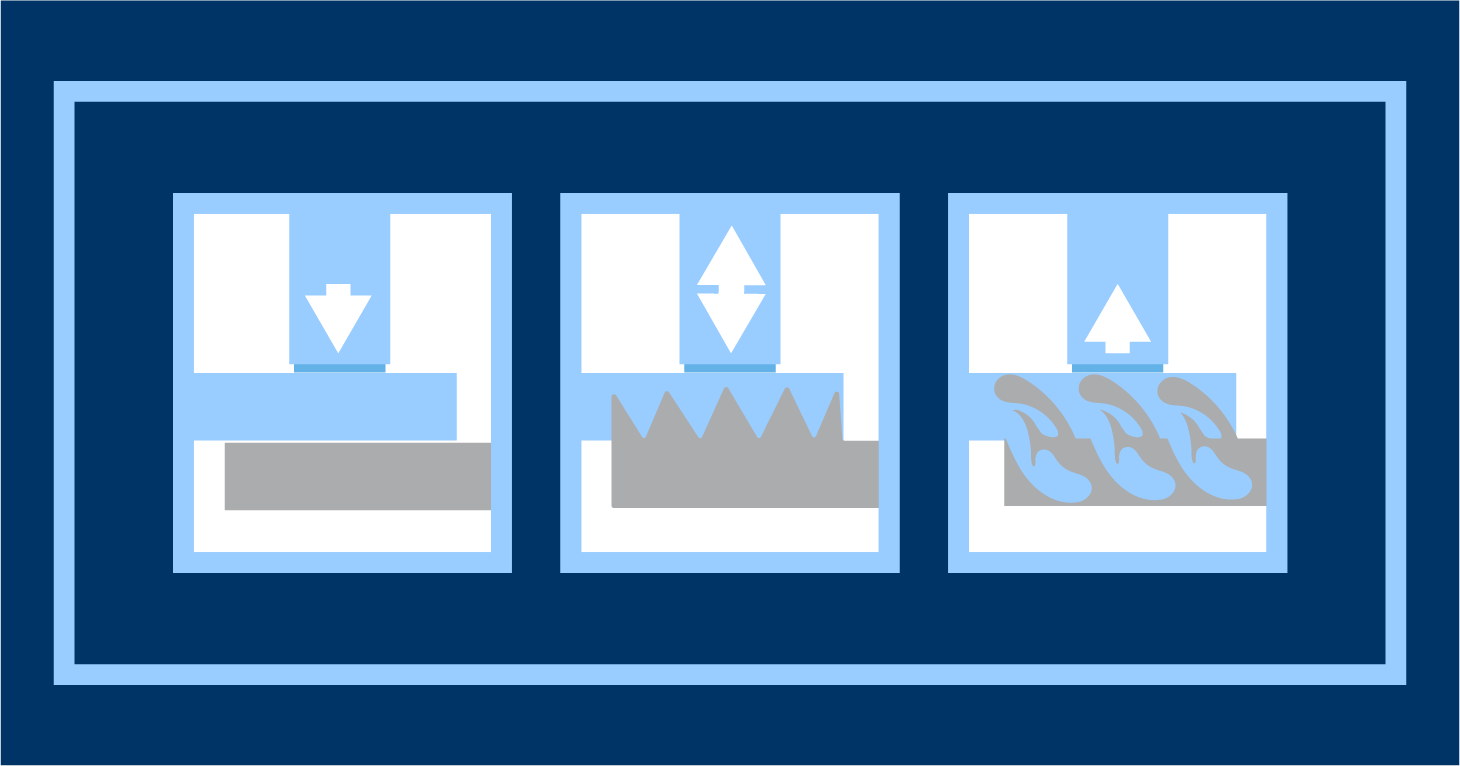

Interpower Ultrasonic Welding: The “Sonic” That Keeps on Booming

Posted on 6/22/20 2:33 PM

In comparison to the fireworks of traditional welding’s molten metal, ultrasonic welding is more a wisp of smoke and a tip of the magician’s hat. In the mid to late 1990s, ultrasonic welding had ventured well beyond its plastics and automotive roots of the 1960s and 1980s respectively. By the dawn of the new millennium, ultrasonic welding had expanded far beyond toys and automobile subsystems—it was wired into the consumer electronics industry, including medical devices and components. Though lacking the cachet of robotics and CAD-CAM, ultrasonic welding was already well versed in the language of manufacturing.

Topics: product design, testing, designing for export, ultrasonic weld

The UL 94 Standard for Safety—Testing the Flammability of Plastics

Posted on 6/8/20 3:00 PM

Underwriters Laboratories’ (UL) 94 Standard for Safety Tests for Flammability of Plastic Materials for Parts in Devices and Appliances defines acceptable flammability ratings of plastic materials for parts in devices and appliances in North America. The First Edition of UL 94 appeared in September of 1972. And on September 16, 1988, the Department of Defense (DoD) adopted UL 94. Since then, there have been several updated editions of UL 94.

Topics: testing, safety, flammability test, ul 94