Recent Posts

The Patterns of Alternate Current Power Cord Plugs—Worldwide

Posted on 1/29/26 9:55 AM

While it’s true that many countries outside of the continental U.S. use North American plugs, and many countries beyond the continent of Europe use European plugs, the majority of countries have their own proprietary plug patterns that adhere to their own standards as well as its safety agency or agencies of choice. Complicated? Yes, and no.

Topics: product design, testing, plugs & sockets

Interpower’s Plug and Socket Tester

Posted on 12/23/24 12:42 PM

Deep inside the bunker of Interpower’s testing facility in Ames, Iowa, (Area 51²?) is an array of testing apparatus for the testing of electrical cable and components to push both newly manufactured and warehoused cable, cords, and components (and cutting-edge prototypes) to extreme limits, often well beyond UL and IEC standards for product compliance. For much of his 20 years, Ron Barnett, Interpower’s Product Development Manager, has procured specialized testing equipment to ensure Interpower’s power cords, cords sets, and components exceed all testing criteria standardized by worldwide agencies such as UL and VDE while personally conducting thousands of tests.

Topics: electrical safety, testing, designing for export, plugs & sockets, product development

Argentina, Australia, and China Standard 10A/250V Plugs & Sockets Have Similar Features, But What are Some Critical Differences?

Posted on 10/27/20 4:17 PM

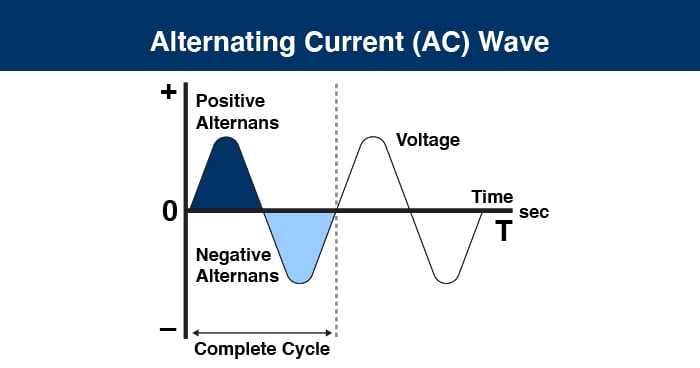

As their standard plug, Argentina, Australia, and China all use the Class I, 10A/250VAC plugs with an Alternate Current (AC) cycle of 50Hz. All three countries have similar plug patterns. All three countries use the international color code for its three conductors: green/yellow (ground), light blue (neutral), and brown (line). And both Argentina and Australia plugs are connected to H05VV-F cable (Harmonized, 300-400V, PVC, Flexible cable) while the China cable is RVV (PVC insulated flexible cable under IEC 60227-5).

Topics: designing for export, plugs & sockets, international plug and socket patterns

Determining the Correct Plug Pattern in a Global Market

Posted on 6/18/18 2:41 PM

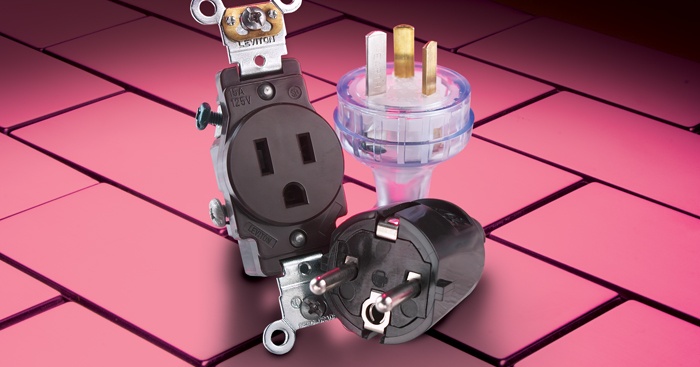

A basic definition of a plug and socket: meeting an electrical need by connecting electrical equipment to a power source. But as simple as that definition sounds, it needs to be noted that there are a number of different plug patterns used throughout the world, making it anything but simple.

Topics: electrical safety, designing for export, plugs & sockets