Recent Posts

The Robust H05BQ-F Harmonized Cable That Even Smokey the Bear Could Endorse

Posted on 9/30/25 2:45 PM

Polymer pioneers in the 1960s and 1970s experimented with multiple thermoplastics to create a low-smoke and zero-halogen (LSZH) cable for the wire and cable industry. Despite achieving low-smoke low-halogen (LSLH) cable, the work of these scientists and engineers was not in vain—in 1979, Richard Skipper of the Raychem Corporation in Menlo Park, California, developed a thermoplastic infused with aluminum trihydrate to create the first LSZH thermoplastic. Aluminum trihydrate [Al(OH)₃] is a white, odorless powder derived from bauxite and commonly used as a flame retardant. The new patent greatly minimized flames and smoke when subjected to intense heat. According to the universal Harmonized Wire Coding System (a one-page download available at the end of this article), the alpha-numeric code of H05BQ-F lets users know the cable is LSZH because of its specific jacket and insulation compositions, as well as its fine-wire flexibility. This cable is further described in paragraph four.

Topics: cable, international cable

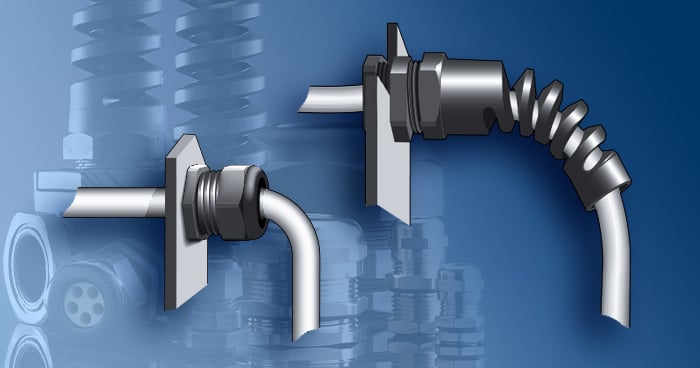

Using Strain Reliefs/Cable Glands to Prevent Acute Bend Radius in Power Cords

Posted on 1/23/24 11:49 AM

Cable is a sleek composite of resins and metals which are vital materials of making world-class power cords and cord sets. While dependable and durable, even essential to modern-day life, cable is also susceptible to acute bending, especially near the point where the cord exits the equipment. Underneath the smooth resinous skin of our example cord, lay three conductors of extruded copper wire. If those wires are extremely bent or otherwise damaged, the result could be loss of electrical continuity or shortened lifespan—protecting your cord’s bend radius helps maintain connectivity. And understanding your cord’s recommended minimum bend radius for cable is critical to the maintenance and longevity of the cable and the machines and equipment powering them.

Topics: cable, product design, cable glands, strain reliefs, product development, bend radius

From Bare Wire to Eye-candy Resins—An American Electrical Cable and Cord Set Manufacturer Holds the Line

Posted on 11/21/22 8:21 AM

Before cord sets are ready to be boxed for shipping, the colorants used in the resins, and the shiny brass and alloys of blades and pins may often resemble an electrical work of art that catches the eye—especially the orange and red cord sets preferred by Australian and Denmark hospitals respectively. Or maybe it’s a clear molded plug, or a hand-wired plug where one can see inside to tell whether every wire retains electrical continuity around the stainless steel ring that binds the conductors. Even standard colors like black and gray offer a semblance of eye candy while manufactured to carry hundreds of volts to equipment across multiple environments.

Topics: cable, USA Made Products, product development

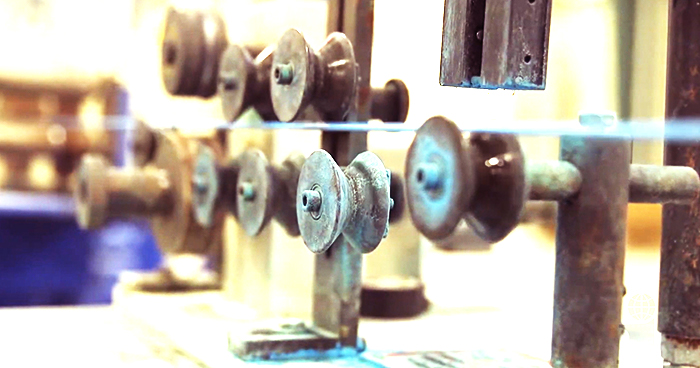

Interpower Cabling

Posted on 5/16/22 8:00 AM

Individual conductor wires are extruded in resin before 2- and 3-wire conductors are cabled into a “twist” of conductors before jackets are extruded over them. The jacketing process is similar to insulating copper wires on the extrusion line. The main difference is jacketing uses more extruded resin making it more time-consuming than insulating. Prior to extrusion, talc is applied to the twisted, insulated conductors which acts as a release-agent for stripping the jacket. This is especially user-friendly when a few millimeters of jacket need to be stripped for crimping wires.

Topics: cable, USA Made Products, product information

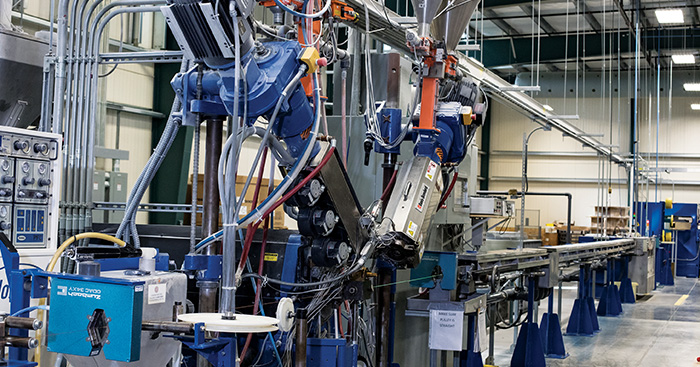

Interpower Manufactured Cable Keeps You Wired

Posted on 5/24/21 4:06 PM

Interpower North American and international cable is manufactured in the U.S.A. at its Lamoni, Iowa, facility. So how is Interpower durable and reliable cable manufactured?

Topics: cable, international cable, USA Made Products, shipping, north american cable