Recent Posts

Add Cord Clips to the Eighth World Wonder: Interpower Angled NEMA 5-15 Cords Offer Eight Different Angles for Tight Spaces

Posted on 4/1/25 8:03 AM

In hospitals, medical clinics, production floor cells, and standard brick-and-mortar offices, the spatial relationship of diagnostic equipment, heavy machinery, and peripheral devices and their AC power outlets can become a tricky geometry to solve—equipment placed tightly against walls where odd angles and tight corners loom. Whether your power cords are 7 or 50 feet in length, you may need cords with angled plugs and cord clips, the latter made of glass-filled polypropylene resin for maximum retention to secure the slack of your excess cord.

Topics: product design, Angled Plugs, product development, 1-week lead-time

Top Interpower® Customer Service Questions of 2024

Posted on 1/29/25 12:14 PM

Hospital-grade Filtered Module Issue? Q: We bought module 83545020 from you to replace a broken one we purchased from a different vendor. We have installed it, but it’s not getting any current. Is the module bad, or are we doing something wrong?

Topics: product design, modules, power cord, EMI, safety, international power components, product development, frequently asked questions, technical-support

Interpower’s Plug and Socket Tester

Posted on 12/23/24 12:42 PM

Deep inside the bunker of Interpower’s testing facility in Ames, Iowa, (Area 51²?) is an array of testing apparatus for the testing of electrical cable and components to push both newly manufactured and warehoused cable, cords, and components (and cutting-edge prototypes) to extreme limits, often well beyond UL and IEC standards for product compliance. For much of his 20 years, Ron Barnett, Interpower’s Product Development Manager, has procured specialized testing equipment to ensure Interpower’s power cords, cords sets, and components exceed all testing criteria standardized by worldwide agencies such as UL and VDE while personally conducting thousands of tests.

Topics: electrical safety, testing, designing for export, plugs & sockets, product development

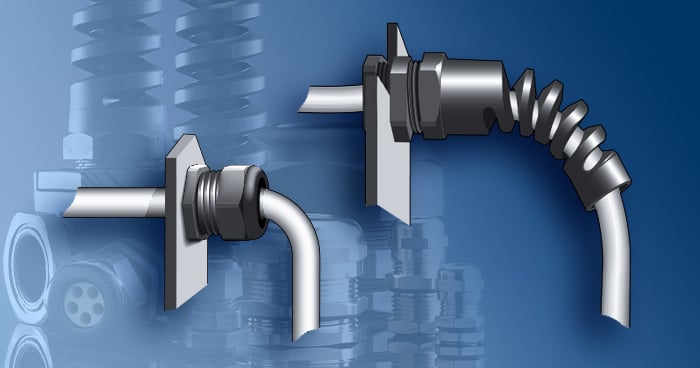

Using Strain Reliefs/Cable Glands to Prevent Acute Bend Radius in Power Cords

Posted on 1/23/24 11:49 AM

Cable is a sleek composite of resins and metals which are vital materials of making world-class power cords and cord sets. While dependable and durable, even essential to modern-day life, cable is also susceptible to acute bending, especially near the point where the cord exits the equipment. Underneath the smooth resinous skin of our example cord, lay three conductors of extruded copper wire. If those wires are extremely bent or otherwise damaged, the result could be loss of electrical continuity or shortened lifespan—protecting your cord’s bend radius helps maintain connectivity. And understanding your cord’s recommended minimum bend radius for cable is critical to the maintenance and longevity of the cable and the machines and equipment powering them.

Topics: cable, product design, cable glands, strain reliefs, product development, bend radius

A Day in the Life of an Interpower Molder

Posted on 12/20/23 2:13 PM

At 7 a.m., Jess, an Interpower Level 2 molder, prepares the ENGEL injection molding machine to mold Continental European (CEE) Cord sets. The CEE plugs will be molded onto 1 mm² international cable, and Jess checks to make sure the 100-lb. CEE mold and proper steel inserts are in place. An additional team member verifies that the correct mold inserts are in place.

Topics: power cord, power cord made to order, international power components, product development, manufacturing, product information, molding