Recent Posts

Benefits of Using a Power Entry Module in Your Electrical Design

Posted on 12/7/20 4:18 PM

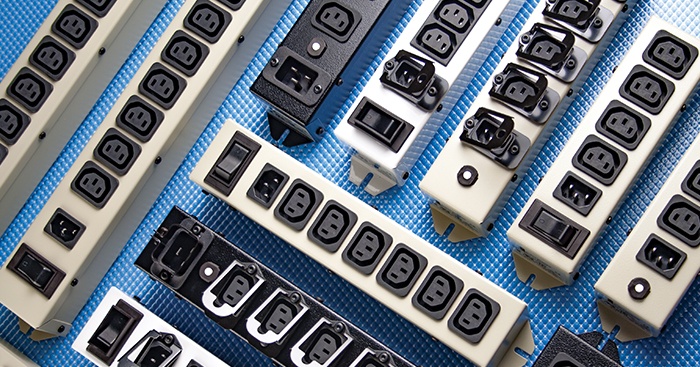

A module is a device that combines multiple functions into a single unit to control power entry. There are several reasons to choose a module over individual components that are installed piecemeal. When choosing a module in your design, the first step is deciding which functions or components your module should contain. Typically an Interpower module offers two to five functions: an inlet, outlet, switch, circuit protection, voltage selector, and a filter.

Topics: product design, modules, designing for export

Argentina, Australia, and China Standard 10A/250V Plugs & Sockets Have Similar Features, But What are Some Critical Differences?

Posted on 10/27/20 4:17 PM

As their standard plug, Argentina, Australia, and China all use the Class I, 10A/250VAC plugs with an Alternate Current (AC) cycle of 50Hz. All three countries have similar plug patterns. All three countries use the international color code for its three conductors: green/yellow (ground), light blue (neutral), and brown (line). And both Argentina and Australia plugs are connected to H05VV-F cable (Harmonized, 300-400V, PVC, Flexible cable) while the China cable is RVV (PVC insulated flexible cable under IEC 60227-5).

Topics: designing for export, plugs & sockets, international plug and socket patterns

New Product Designs

Posted on 8/17/20 1:36 PM

Topics: product design, designing for export, product development

Designing for Compliance

Posted on 7/20/20 1:34 PM

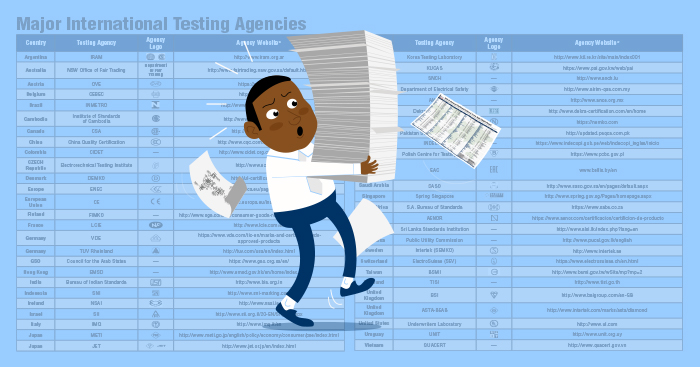

In the beginning stages of a new product’s design, engineers and product developers usually know how their products will be marketed. That decision determines which national or international standards need to be followed, and which safety agency they will work with in obtaining approvals for their products.

Topics: designing for export, compliance standards, adding marketability

Accessory Power: Making Product Exporting a Cost-effective Reality

Posted on 7/6/20 4:22 PM

Accessory Power systems are literally passports to global markets offering end users the versatility to connect to country-specific power mains.

Topics: designing for export, IEC, Accessory Power, Accessory Power System