Interpower Manufactured Cable Keeps You Wired

Posted on 5/24/21 4:06 PM

Interpower North American and international cable is manufactured in the U.S.A. at its Lamoni, Iowa, facility. So how is Interpower durable and reliable cable manufactured?

This intricate process includes three separate operations: insulating, cabling, and jacketing. During the insulating process, plastic is extruded over the stranded copper wire with some gauges at rates over 1,000 feet per minute. Meanwhile, monitoring along with multiple real-time quality checks ensure every product meets all specifications.

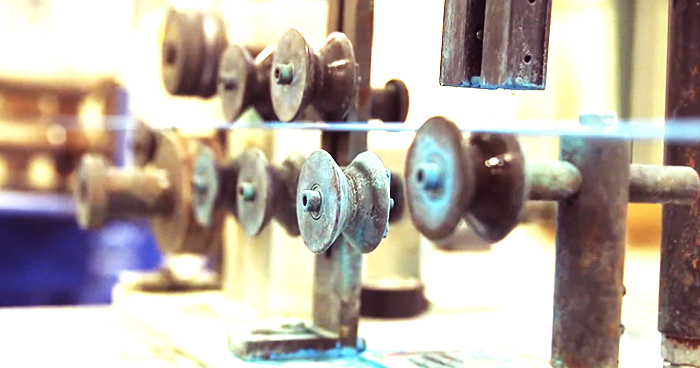

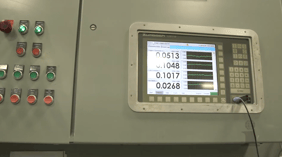

Immediately after extrusion the cable is measured, then remeasured once it has cooled. The insulated wire is spark-tested to ensure there is 100% coverage over the copper. The wire is then placed on a reel for processing later at the cabler machine.

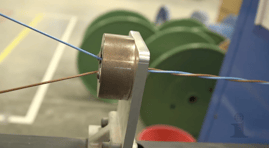

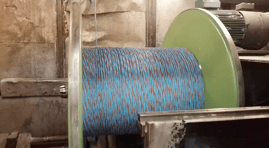

The cabling process takes the number of individual reels of insulated wire and twists them together into one group of insulated wires on the cabler machine. The finished product determines the number of insulated wires. Typically there are three in the process, a line wire, neutral wire, and a ground wire.

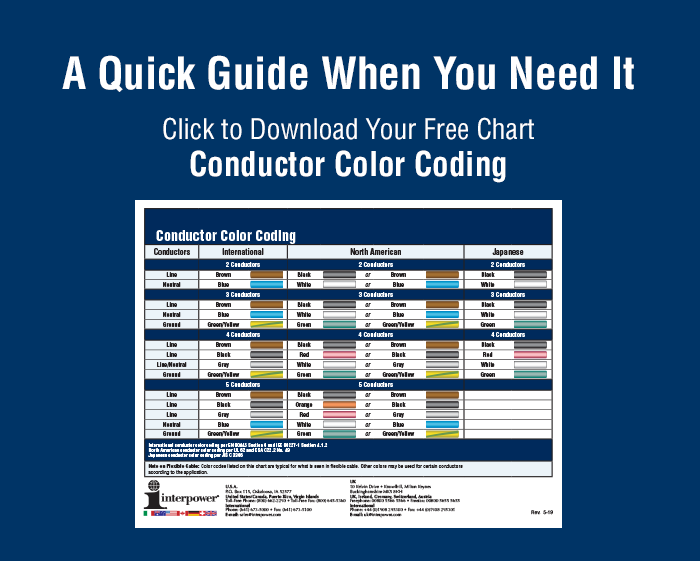

The color of the insulated wires depends upon customer preference, but typically the line wire is brown, the neutral blue, and the ground green with a yellow stripe. The “length of lay” specification in the cabling process is important, and is the lay length required for one wire to complete a full revolution of the strand around the diameter of the conductor. Why is lay length so important? The nontechnical answer is flexibility—the cabled product can now be reeled for jacketing.

Jacketing is basically the same process used in insulating the bare copper on the extrusion line. Jacketing is typically a slower process than insulating since more plastic is extruded. Prior to extrusion, talc powder is applied to the bunched product. The talc acts as a release agent for stripping the jacket.

The jacketed product exits the extruder and goes immediately into a chilled water bath for the next 40 feet. After the jacket dries it is marked with the necessary information such as size, approvals, and the lot code. The jacket's outside diameter is measured in real time to ensure it meets the specifications. The finished product is then placed onto a reel for shipment.

Quality inspections are also conducted at Interpower’s testing labs in both Lamoni and Ames, Iowa, to ensure the cable meets the specifications that can’t be done in real time on the extrusion line or cabler.

Interpower offers no minimum order or dollar requirements. Interpower offers a 1-Week U.S. manufacturing Lead-time on non-stock Interpower products, and Same Day Shipments available on in-stock items.

For more information on cord clips or our complete line of products, please contact our Customer Service Representatives at (800) 662-2290, or e-mail at info@interpower.com. Representatives are available to answer your questions from 7 a.m. to 6 p.m. CST.

Topics: cable, international cable, USA Made Products, shipping, north american cable