Recent Posts

Interpower® 1-Week Lead-Time on Cords & Cord Sets Returns

Posted on 5/30/23 2:40 PM

Since its inception in 1975, the Interpower Corporation has steadily expanded its line of electrical cable, cords, cord sets, and components. Still, world-class products are only truly world-class if they arrive with protective packaging and reliable delivery. From the production floor to value-added options on packaging, labeling, and shipping, Interpower prides itself in meeting customers’ ever-changing needs.

Topics: USA Made Products, product information, 1-week lead-time

Is Reshoring Manufacturing Back to the U.S. the Next Industrial Revolution?

Posted on 4/24/23 2:17 PM

For those working directly with supply chains, the memories of lockdowns and ongoing supply chain disruptions are likely indelible. Newton’s Third Law of Motion states, “For every action, there is an equal and opposite reaction.” The “reaction” is still knocking around the Supply Chain enough to give purchasers, shippers, and receivers a mild case of PTSD.

Topics: USA Made Products, shipping, Global Markets

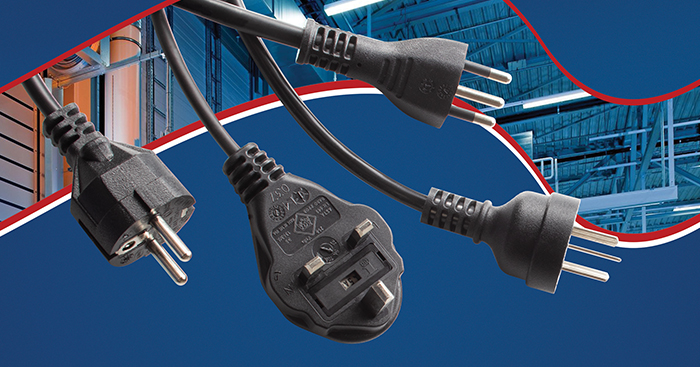

Four Key Decisions in Selecting Country-Specific Cords & Cord Sets

Posted on 3/21/23 11:31 AM

The selection of country-specific power cords and cord sets is vital for manufacturers and exporters as to ensure compliance with country-specific plugs and power cords, North American and international cable, and components. Choosing a cord or cord set usually involves five steps:

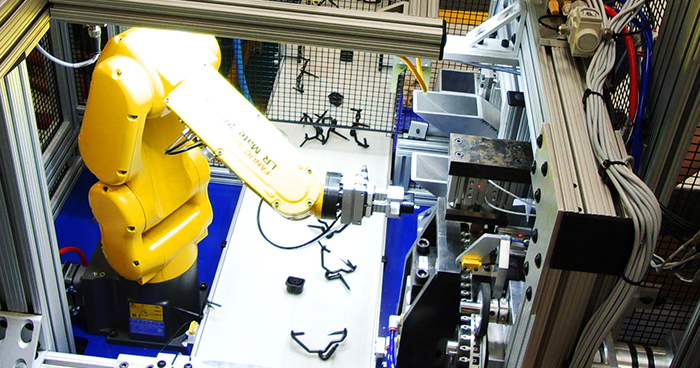

Interpower Adds New IEC 60320 Automated Production Cell as Lead-Times Soften

Posted on 2/20/23 3:05 PM

Interpower has installed a new automated contact insertion cell to ramp up production of IEC 60320 Sheet F and Sheet J outlets at its headquarters in Oskaloosa, Iowa.

Electrical Cord & Component Manufacturing, Accessory Power, and Warehousing

Posted on 1/23/23 8:35 AM

Topics: designing for export, Accessory Power, supply chain, Global Markets