Not All Cord-locking Mechanisms Are Created Equal

Posted on 6/13/22 4:15 PM

Easy-to-disconnect connector locks and other cord-locking mechanisms are convenient tools for anchoring cords to inlets to prevent abrupt disconnects, but not all manufactured versions are created equal. Avoid easy-to-disconnect locking mechanisms which gouge or shave away the ground blade of the inlet during abrupt disconnects or improper usage and removal.

Easy-to-disconnect connector locks and other cord-locking mechanisms are convenient tools for anchoring cords to inlets to prevent abrupt disconnects, but not all manufactured versions are created equal. Avoid easy-to-disconnect locking mechanisms which gouge or shave away the ground blade of the inlet during abrupt disconnects or improper usage and removal.

Such abrasion may occur quickly or over time depending on the design and number of improper or abrupt disconnects. This may cause arcing, which subsequently leads to micropitting and carbonized buildup inside the connector and on the inlet blades when cords are abruptly disconnected. Arcing and buildup may subsequently lead to a loss of electrical continuity or worse, a fire hazard.

Typically, connector locks and other cord-locking mechanisms are used for IEC C13/C14, C17/C18, C19/C20 inlets and connectors, and Sheet E/Sheet F and Sheet G/Sheet H, Sheet I/J plug connectors and outlets. Other popular IEC combinations are available as well.

Tool-free Locks

Interpower tool-free connector locks were designed to prevent abrupt disconnection without causing buildup and arcing—one angle of the steel connector lock is flexed against the connector body holding it in place. The tool-free locks are also E-coated, a process where the metal is immersed in a water-based solution that contains a paint emulsion. An electric current provides the catalyst to cause condensation in the paint emulsion ensuring the paint flows across the entire surface of the lock.

Interpower tool-free connector locks were designed to prevent abrupt disconnection without causing buildup and arcing—one angle of the steel connector lock is flexed against the connector body holding it in place. The tool-free locks are also E-coated, a process where the metal is immersed in a water-based solution that contains a paint emulsion. An electric current provides the catalyst to cause condensation in the paint emulsion ensuring the paint flows across the entire surface of the lock.

Locking-screw Connector Locks

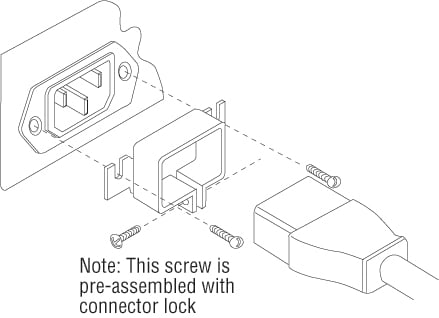

If a more robust connection is needed, Interpower offers locking-screw connector locks which lock to the inlet with mounting screws to prevent abrupt disconnections. These connector locks accommodate many IEC connector/inlet and plug connector/outlet combinations. Cord sets remove easily without disrupting the connector lock. Locking-screw connector locks are only used with screw-mounted power inlets.

Locking-screw Installation Instructions:

- To ensure proper alignment of the clamp with the connector, loosen the two mounting screws on the sides of the power inlet.

- Slip the connector lock under the mounting screws and leave the mounting screws loose.

- Insert the cord set through the connector lock into the inlet.

- Tighten the locking screw on the connector lock so that the clamp firmly grips the connector on the cord set.

- Tighten the two mounting screws on the sides of the inlet. The connector lock is now secured on the connector and chassis so that the cord set may be easily removed and inserted in the future.

Locking the Cord Set:

Locking the Cord Set:

(Note: After the installation is completed, it is not necessary to adjust the side-mounting screws again.)

- Insert the cord set through the lock into the connector. Be sure that it is pushed completely into the connector.

- Tighten the locking screw on the cord set connector so that the lock firmly grips the cord set.

Removing the Cord Set:

(Note: After the installation is completed, it is not necessary to adjust the side mounting screws again.)

- Loosen the locking screw on the cord set connector lock.

- Remove the cord set.

Whether it’s medical, financial, or inventory data, why risk losing data before it gets safely stored? Or why ruin an inlet, outlet, or a cord set with abrupt disconnects? For more information on lock connectors, please click Interpower Connector Locks.

Topics: electrical safety, power cord, connector locks, connectors