Recent Posts

The Patterns of Alternate Current Power Cord Plugs—Worldwide

Posted on 1/29/26 9:55 AM

While it’s true that many countries outside of the continental U.S. use North American plugs, and many countries beyond the continent of Europe use European plugs, the majority of countries have their own proprietary plug patterns that adhere to their own standards as well as its safety agency or agencies of choice. Complicated? Yes, and no.

Topics: product design, testing, plugs & sockets

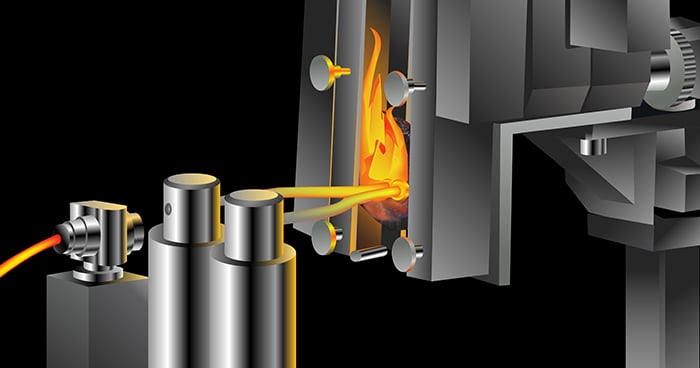

UL 94 Flammability Testing Versus the IEC 60695-2 Glow-Wire Testing

Posted on 12/31/25 9:57 AM

UL 94 Testing Underwriters Laboratories’ (UL) 94 Standard for Safety Tests for Flammability of Plastic Materials for Parts in Devices and Appliances defines acceptable flammability ratings of plastic materials for parts in devices and appliances in North America, including cord sets. The First Edition of UL 94 appeared in September of 1972. On September 16, 1988, the Department of Defense (DoD) adopted UL 94.

Topics: testing, safety, flammability test, ul 94

A Partial Review of the CEE 7 Standard’s Plugs and Sockets

Posted on 11/21/25 10:54 AM

Note: Though the CEE 7 standard was superseded by the IEC 60083 standard, many of the plugs and sockets have changed little in design—but perhaps more in material—since the last CEE 7 update was published. Despite the very earliest CEE 7 plugs and sockets having been more or less obsoleted, you will still find a few of them hiding out indoors in a few countries—specifically CEE 7/1 and 7/2, which were not grounded (earthed) plugs and sockets. However, the 7/3 German Type F socket that came soon after the 7/1 and 7/2 was the first grounded socket in the CEE 7 series.

Topics: compliance standards, CEE

The International Electrotechnical Commission—Setting the Standards

Posted on 10/31/25 8:29 AM

What the IEC Does and Doesn’t Do The International Electrotechnical Commission (IEC), né Commission électrotechnique internationale, is an international standards organization headquartered in Geneva, Switzerland, which writes and publishes international standards. IEC standards have been adopted by a majority of nations worldwide. Unlike safety agencies such as UL or VDE, the IEC does not test or certify its IEC 60320 electrical components—the safety agencies do that. While the standards are not codified or enforced by the IEC, the agencies representing countries worldwide—such as those listed above—can demand compliance from manufacturers to meet IEC standards as written. In Europe alone, 80% of European and electronic standards are IEC standards.

Topics: Accessory Power

The Robust H05BQ-F Harmonized Cable That Even Smokey the Bear Could Endorse

Posted on 9/30/25 2:45 PM

Polymer pioneers in the 1960s and 1970s experimented with multiple thermoplastics to create a low-smoke and zero-halogen (LSZH) cable for the wire and cable industry. Despite achieving low-smoke low-halogen (LSLH) cable, the work of these scientists and engineers was not in vain—in 1979, Richard Skipper of the Raychem Corporation in Menlo Park, California, developed a thermoplastic infused with aluminum trihydrate to create the first LSZH thermoplastic. Aluminum trihydrate [Al(OH)₃] is a white, odorless powder derived from bauxite and commonly used as a flame retardant. The new patent greatly minimized flames and smoke when subjected to intense heat. According to the universal Harmonized Wire Coding System (a one-page download available at the end of this article), the alpha-numeric code of H05BQ-F lets users know the cable is LSZH because of its specific jacket and insulation compositions, as well as its fine-wire flexibility. This cable is further described in paragraph four.

Topics: cable, international cable