New Products: Designing for Compliance

Posted on 12/30/19 7:31 AM

Keep the end destination in mind when beginning to design a new electrical or electronic product.

At the beginning of a new product design, decide where the product will be marketed. That decision will determine which national and/or international standards need to be followed, along with selecting a safety agency to work with to obtain appropriate approvals for the product.

Certifying That a Product is Safe for Use

Designing for compliance with product safety requirements starts with an understanding of where the standards originate and who certifies that the product satisfies the requirements. Within those standards are specifications the new product will need to attain in order to achieve the safety approval. An approval certifies that a product is safe for use in the intended application. Plus, conformity with national and international product safety regulations is required for doing business in many industrialized countries.

There are several reasons why electrical or electronic equipment manufacturers need to follow product safety regulations when designing a new product.

- In some countries, laws require that all electrically-powered products be evaluated by an appointed authority before connection to the mains.

- Some kinds of equipment, such as devices intended for use in the home, may not be sold without being tested and approved by the appropriate safety agency.

- Even if the products are not subject to mandatory testing or inspection prior to sale, in some countries the seller and manufacturer do assume a significant amount of product liability exposure in the event of a product failure in which someone is injured or there is a loss of property due to fire.

- The reliability of the product is enhanced by ensuring that the product being sold is safe when it meets national and/or international expectations for safety.

Standards and Safety Testing Agencies

There are two types of agencies: standards and testing. The standards agency creates written standards and documents construction and performance requirements. The testing and/or certification agency performs tests on the products to ensure they satisfy the standards that have been written.

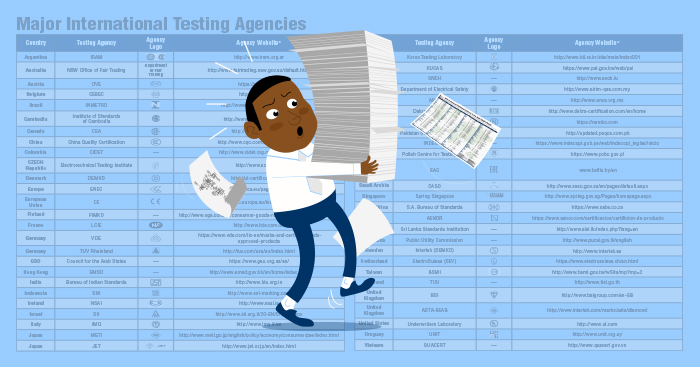

“Many countries around the world have their own standards and testing agencies to verify that products brought into their country will work safely and effectively,” explained Joe Caligiuri, Product Compliance Specialist at Interpower. “Contact a safety agency within the country you’re planning to sell the product in. While requirements vary per agency, most require an application to be filled out regarding the product. The agency may ask for a sample of the product and technical information, such as product specifications.”

Product safety approvals are based on standards within a given country or region, but an agency approval for a given product may be accepted in other countries. If this new product is to be sold in more than one country, Joe suggests checking with those countries to see if they accept another agency’s test report. For example, many of the countries throughout Europe will accept the test results from the German VDE or TUV safety agencies. In Asia, however, it varies widely—some countries accept another agency’s test report, others don’t; some require that the testing be done only in that specific country. “It helps to make the process smoother and keep costs down if you can find a safety agency approval that is accepted in more than one country,” he added.

Use Approved Power System Components

It is recommended to use agency-approved power system components in the product design, rather than unapproved ones. Few producers of electrical or electronic equipment can economically justify the use of unapproved power system components. Some of the reasons for this include:

- Many agencies reserved the right to test unapproved power system components separately, which may cause delays and create extra charges for testing.

- Extra component testing, particularly if not foreseen at the time of submittal, may cause delays. Additional component samples may be required for further testing.

- While unapproved components may be accepted by an agency, the approval may only allow their use in that specific application.

- It is possible for a component manufacturer to change something in a part without the manufacturer of the product being aware of it. If unapproved parts are used and something changes, this could cause a company to fail an inspection.

Customer Expectations

Another reason for having a safety approval on the product: customers expect it. Interpower’s product philosophy is oriented towards making compliance easy for the electrical or electronic product designer. Wherever possible, individual power system components offered by Interpower, especially those with the Interpower® trademark, have been designed so that a single component can be used in as many different countries as possible.

Additional Resources

Interpower offers a list of international testing agencies on the website. You can also download the printable chart.

Interpower offers free technical support. For further assistance, please see Interpower’s contact information below.

Topics: designing for export, testing agencies, international power components