Interpower® Healthy Hospital-grade Power: NEMA 5-15, 5-20, 6-15, & 6-20 Cords

Posted on 12/22/22 8:30 AM

So, how are hospital-grade cords like bottlenecked supply chains? The longer the cord or the chain, the slower the “cargo” is transported whether electrons or goods.

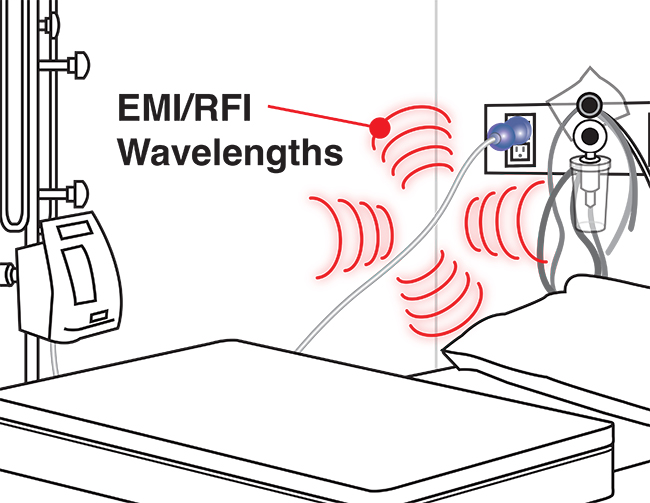

A hospital-grade cord manufactured beyond a certain length may overheat from electrons pushing too hard across conduits of copper and jacket-related impedance while creating more electromagnetic interference (EMI) due to its additional amounts of copper and other alloys. After 50 feet, cords are derated per UL, and the risk of a fire hazard is increased. Due to more alloys, longer power cords create more EMI which may cause sensitive medical equipment to malfunction or short circuit. Longer cords tend to produce antennalike qualities and attract additional signals.

“If you’re using medical cords longer than 12-15 feet,” said Dan Ford, Interpower Technical Support Specialist, “it becomes more difficult to meet the equipment standard requirements for resistance and leakage current for the entire electrical system. You don’t want high levels of EMI in equipment attached to the patient.” There are numerous standards for hospital-grade cords requiring exacting specifications and tolerances. Yet there is one standard conspicuously absent.

“Currently there is no UL standard for hospital-grade cord length,” Ford said. “This is likely due to medical standards covering a host of equipment with differing requirements.” Two diametric examples of those standards range from the UL Abrupt Removal Test (UL 817, 18.2.4.1.) where a hospital-grade plug attached to a cord bearing a 10-lb weight is dropped to ensure the pull force on the cord does not damage the internal plug terminations by repeatedly impacting the cord at the cord exit. The plug blades are inspected to see how far the blades have bent. The crimping is also inspected to see if it has pulled away from the copper conductors.

An international example of hospital-grade standards comes from an International Electrotechnical Commission (IEC) requirement for the jackets of hospital-grade cords used near hospital beds to maintain their abrasion resistance when encountering the wheels of hospital beds (IEC 60601-2-52). This standard ensures that wheels rolling over or sitting on the cord do not cut, slice, or shred the outer jacket which may expose bare wire—the cord jacket must be the H05-BQ-F variety.

Depending on the application, EMI leakage in medical equipment is often measured in mircroamps versus milliamps if equipment is near the patient or there is the possibility of interference affecting medical equipment.

Cord Calculation & Testing

However, shortening the length of the cord connected to the mains power may not solve all EMI issues. Let’s say you add an EMI filter. Now you’ve added a layer of redundancy to lower your interference. You should be good to go, right? Maybe. Ford presses home the point of “cord calculation” for every electrical design.

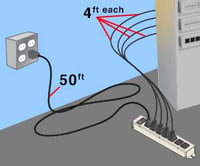

“Let’s say you plug your country-specific plug into the wall outlet (mains power) and the opposite connector end into an Accessory Power Strip (APS), then plug additional cords into the strip that run to peripheral equipment, you must calculate the total cord length (not just the main power cord) to get total amount of resistance and leakage current,” Ford said. That is, a 50-foot cord, plus 4 ten-foot cords into the same system would calculate to 90 feet of resistance and current leakage. This may affect equipment performance, or take you beyond the limits of the specific standards you are complying with.

“Let’s say you plug your country-specific plug into the wall outlet (mains power) and the opposite connector end into an Accessory Power Strip (APS), then plug additional cords into the strip that run to peripheral equipment, you must calculate the total cord length (not just the main power cord) to get total amount of resistance and leakage current,” Ford said. That is, a 50-foot cord, plus 4 ten-foot cords into the same system would calculate to 90 feet of resistance and current leakage. This may affect equipment performance, or take you beyond the limits of the specific standards you are complying with.

All Interpower cords and components are manufactured in accordance with Interpower’s product quality plan: hipot testing, continuity testing, ground testing, and inspections after each process.

“We test more than is required by the standards for our own benefit as well,” Interpower Product Development Manager Ron Barnett says. “We go beyond the standards because it lends better reliability to our design—products become more reliable in that regard.”

Interpower offers same day shipping on in-stock hospital-grade cords. Our molded cords and cord sets are made in Lamoni and Oskaloosa, Iowa. Unlike cords produced in Asia where ports may be in lockdown for weeks or even months, Interpower cords ship straight from America’s heartland.

Claim your Free White Paper Below!

Topics: Designing for North America, hospital-grade cords, North American Hospital-Grade Cords, Hospital-Grade Testing