IEC Components

Posted on 10/17/23 9:00 AM

Passports to Global Markets

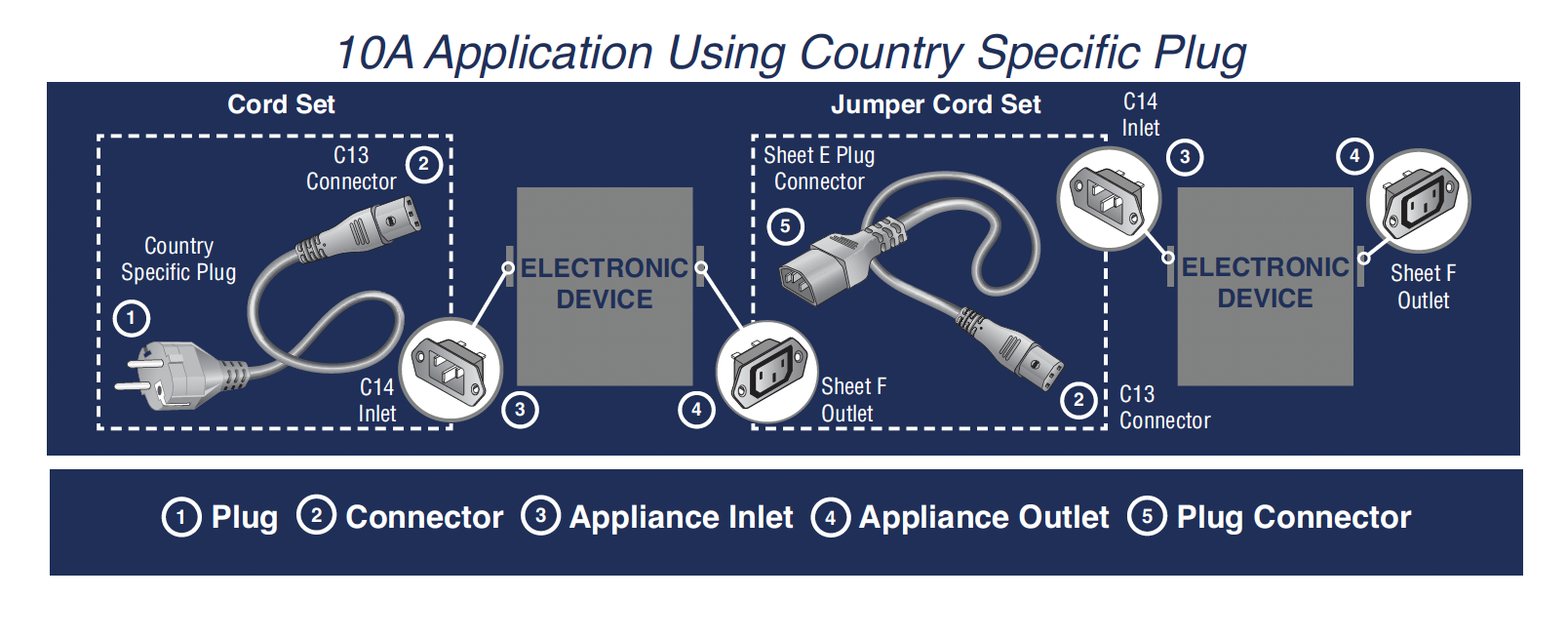

Designing an accessory power system using IEC 60320 components eliminates the need for end users worldwide to reconfigure cords once they arrive. By creating a common interface, IEC 60320 products create a common connector interface making it possible for entire designs to be built around them. Like having a passport at the ready for traveling abroad, IEC 60320 products complement any country-specific plug if the opposite end of the cord is terminated with an IEC connector to plug into an accessory power strip or a power distribution unit. It also allows the option of not having to warehouse country-specific plugs.

Exactly How?

An accessory power system combines a country-specific plug to tap into the mains power at the wall socket. The opposite end of the cord, made of either North American or international cable, is terminated with an IEC molded or hand-wired IEC connector which plugs into the inlet housed in the accessory power strip (APS). The APS houses multiple IEC 60320 outlets that can now accept IEC 60320 jumper cords, e.g., Sheet E or I plug connectors into the APS. Most commonly, the other end of this sheet appliance coupler is terminated with a C13 or C19.

Accessory Power Strips & Power Distribution Units

The APS and PDU are especially beneficial when there’s insufficient panel space to power up equipment, and where wall outlets are at a minimum. Even if your office or production facility has an array of wall outlets and longer cords to reach them, those longer cords will cause more EMI (more conductor length, more interference), and you may wind up with a cat’s cradle of wires to trip over. Any power cord longer than 50 feet becomes derated, and potentially becomes a fire hazard as electrons push harder through the impedance to get to where they’re going.

The APS and PDU are especially beneficial when there’s insufficient panel space to power up equipment, and where wall outlets are at a minimum. Even if your office or production facility has an array of wall outlets and longer cords to reach them, those longer cords will cause more EMI (more conductor length, more interference), and you may wind up with a cat’s cradle of wires to trip over. Any power cord longer than 50 feet becomes derated, and potentially becomes a fire hazard as electrons push harder through the impedance to get to where they’re going.

Cord Clips

While cord clips aren’t considered accessory power components, they do complement accessory power since multiple cords may often run from the wall several feet before entering an APS or PDU. Cord clips help prevent injuries such as tripping over excess cord. It also extends cord life by keeping it away from machinery and tools, and preserves the jacketing by allowing less drag. It also minimizes the chance of excess cord catching on objects and surfaces, which may cause disconnections or bent plug blades.

While cord clips aren’t considered accessory power components, they do complement accessory power since multiple cords may often run from the wall several feet before entering an APS or PDU. Cord clips help prevent injuries such as tripping over excess cord. It also extends cord life by keeping it away from machinery and tools, and preserves the jacketing by allowing less drag. It also minimizes the chance of excess cord catching on objects and surfaces, which may cause disconnections or bent plug blades.

Despite the universe of resin compounds listed on UL’s website, sometimes finding the perfect resin with the right additives is challenging, especially when mixing resin compounds with nonresinous material. Interpower’s cord clip can be molded onto 3 x 16 and 3 x 18 AWG cords as well as the 3 x 18 VCT-F Japanese cords, and is constructed of a glass-reinforced Polypropylene resin compound to ensure molding consistency and optimal retention.

The clip is set at a convenient 4.75 inches behind the plug as an optimal distance after much experimentation and testing. The clips come in gray and black and are made in the U.S.A.

Additional Resources

For more information on Accessory Power Systems, see the complete line of Accessory Power Strips and Power Distribution Units available at Interpower. See also the APS and PDU highlighted on the Featured Product page.

Topics: product design, designing for export, IEC 60320